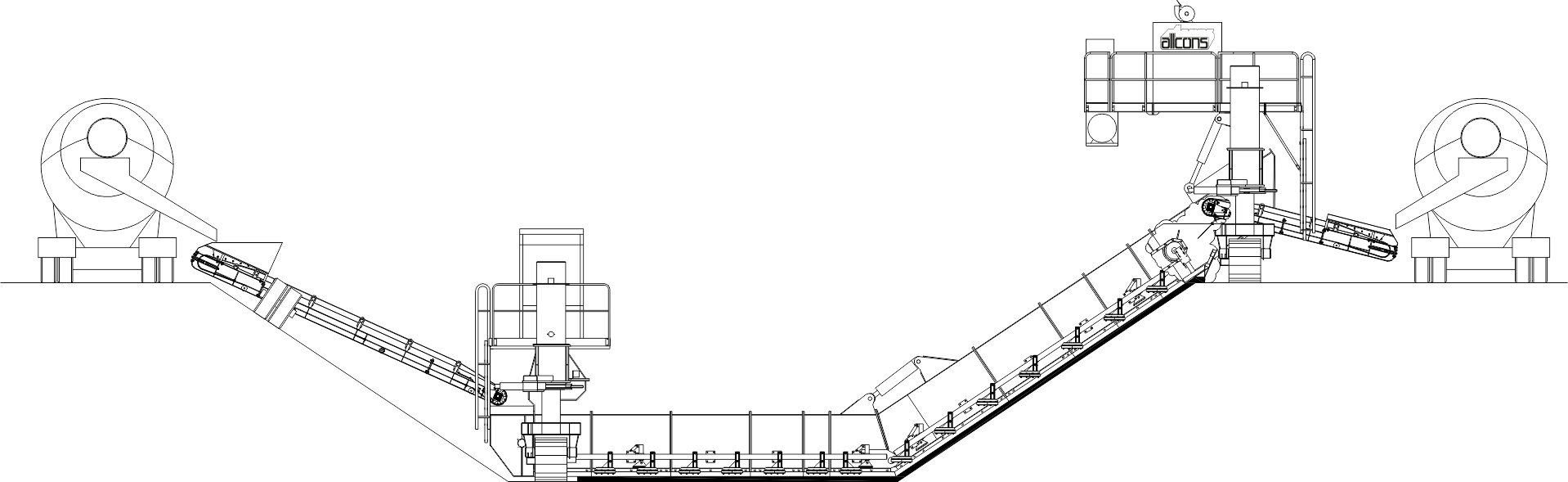

Concrete Hinge Liner for large canals

| Specification | |

|---|---|

| Concrete handling | Typical 75m3/hr |

| Concrete Joints | Hydraulically driven joint cutter |

| Chassis | Four crawler tracks ea. provided with heavy duty jacking column with 800mm lift and swivelling by 90° |

| Engine | Water cooled diesel engine with 300hp (224kW) continuous power rating |

| Generator | High frequency generator with 60kVA, incl. electric vibrators |

| Working speed | Continously adjustable: 0 – 7m/min |

| Transportation speed | Continously adjustable: 0 – 18m/min |

| Machine Control | Automatic steering and height adjustment with single stringline system |

| Accessories | Night lighting system, daily maintenance tools, operation and maintenance manuals |

| Curing |

|

Technical Description

all params can be adjusted to customers needs

Power Station

- Water cooled diesel engine 300hp Cummins QSC8.3 C-300 (224kW) continuous power rating, six cylinder, Europe Stage IIIA / US Tier 3

- Hydrostatic pumps, high quality type such Sauer Danfoss, Rexroth

- Power unit enclosure is noise insulated

- Module includes access ladder and maintenance platform with hand railing

- Power unit designed to work in hot / tropical climates

Chassis

- Four oscillating crawler tracks (size B4), approx. 600mm wide and 1550mm long center to center with planetary gear reduction box

- Each crawler track with heavy duty jacking column provided with 800mm lift cylinders and hydraulic steering

- The crawlers can be swivelled by 90° for moving in lateral direction

- Low speed continously adjustable: 0 – 7m/min (for working)

- High speed continously adjustable: 0 – 18m/min (for traveling)

- Two hydraulically driven pivoting hinges to kink the main frame

- The machines are designed for working in slopes with inclination or in flat terrain. With additional parts the slope inclination can be easily adjusted.

- Main frame of heavy duty construction with removable sections with bolted flanged connections on slope and bottom, and adjustable slipform pans to match the canal slope and bottom width.

Miscellaneous

- Emergency stop buttons on all four corners of the machine, at operator control console and at the power station

- DC night lighting system, 2 ea. lamps front and 2 ea. lamps rear

- Water reservoir approx. 1m3 with support. The water system comes with water pump, plumbing and hose with spray nozzle.

- Tool box with daily maintenance tools

- Operation and maintenance manuals in CD ROM format

Machine Control

- Manual steering and height adjustment, supported by status display

- Automatic steering and height adjustment with single stringline system, cross slope via inclinometer

- Including sensors: 3 stringline sensors, 3 inclinometers

- Anti-torsion control system

- Display for machine status and for fault / self-diagnostic

- Operator control console complete with user friendly allcons software

- Networked PLC system with fault / self-diagnostic capability

- Single electrical lockout key for all electrical provided on power unit

Concrete Paving Equipment

- Adjustable slipform length and inclination to modify compacting pressure

- Concrete receiving and distribution system designed to handle concrete at a maximum rate of 75m3/hr via one distributor conveyor belts. The distribution of the concrete is done by a paddle chain system with hydraulic motor drive.

- The compaction of the concrete is done by 26 electric vibrators

- Dummy joints are cut in lateral direction of the canal by means of hydraulically operated joint blades, manually or automatically triggered.

- Longitudinal joints are continuously cut by relocatable keel bars which are mounted at the bottom of the slipform.

- Stairs and walkways mounted at the rear end of the concrete liner

- Variable canal depth: Upper concrete curb forming headers, manually adjustable to vary canal depth.

Fields of application

Large Canals

from 9m top width