Concrete Face:

- allcons Hinge Concrete Liner / Series PC6000HS

for continuous lining of canal and river beds, up to 180m3/hr concrete with standard feeding system, much higher production rates on request available.

- allcons Hinge Working Bridge / Series BC6400HS

mobile working platform with equipment for finishing and curing the concrete, including a diesel electric generator for decentralized power supply.

Asphalt Concrete Face:

- allcons Hinge Asphalt Liner / Series PA6000HS

for continuous lining of canals and river beds, up to 450t/hr asphalt with standard feeding system, much higher production rates on request available.

- allcons Winch Carriage / Series WW

for working safely on canal slopes and embankment dams with road rollers for compacting the asphalt, or cold milling machines for rehabilitation projects

Applications for Bucket-wheel Excavators

and Telescopic Liners

Allcons Hinge Construction Machines are very versatile. The machine frames are divided into sections,

so they can be adapted to varying canal section shapes according to desire. Many configurations are possible:

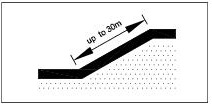

Half Section

Larger canals can be built by using the half section configuration. This enables the handling of up to 30m slope length in one pass.

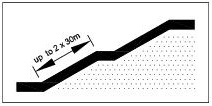

Extended Half Section

For longer (stepless) slopes, one of the running gear can drive within the slope, so 60m can be achieved

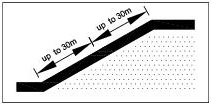

Separated by Berms

For even larger canal slopes or embankment dams, it may be necessary to split the slope into more sections, separated by berms, so it is possible to produce slopes with any length

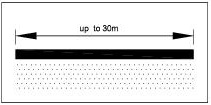

Flat Terrain

The Hinge Construction Machines can also be used in flat terrain, so there is no need for conventional machines for trimming and lining the canal floor

Specifications of related Machines

Series WW

Winch Carriage

Series PC6000

Concrete Liner for large canals

Series PA6000

Asphalt Paver for large canals

Series BC6000

Hinge Working Bridge, for large Canals